YLM Company's Pipe Bending Machines (5-Axis and 3-Axis)

Ishigaki EVTech Solutions utilizes YLM Company's advanced pipe bending machines, including 5-axis and 3-axis models. These machines enable the precise and efficient bending of pipes, contributing to the production of accurate and durable components.

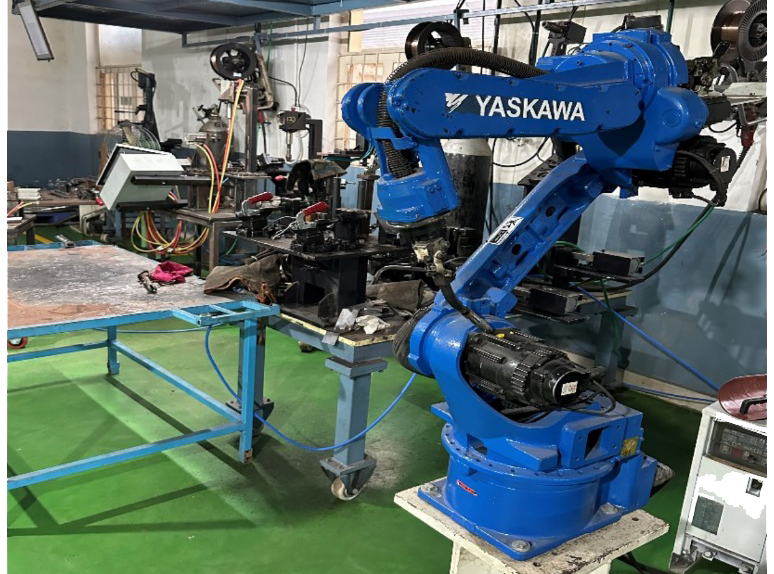

Yaskawa Robotic Arms

The company employs multiple Yaskawa robotic arms for precise welding applications. These robotic arms offer flexibility and accuracy in performing welding tasks, ensuring consistent and high-quality welds.

PANASONIC MIG/TIG Welding Machines

Ishigaki EVTech Solutions utilizes Panasonic MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding machines. These machines provide precise and efficient welding capabilities, contributing to the production of strong and reliable welded assemblies

CNC Fine Boring Machines

The company utilizes CNC (Computer Numerical Control) Fine boring machines for precise boring of Head pipes. These machines ensure accurate dimensions and smooth finishes, meeting the required specifications of the components.

Pneuematic Presses

Ishigaki EVTech Solutions has a range of Pnuematic presses ranging from 10 tonnes to 150 tonnes. These presses are utilized for various operations, such as forming, punching, and stamping, enabling the company to manufacture components with precision and efficiency.

In-house Tool Room

Ishigaki EVTech Solutions has an in-house tool room equipped with the necessary machinery and equipment to manufacture pneumatic-based fixtures, gauges, and tools. This capability allows the company to maintain control over the entire manufacturing process, ensuring high-quality and customized solutions.