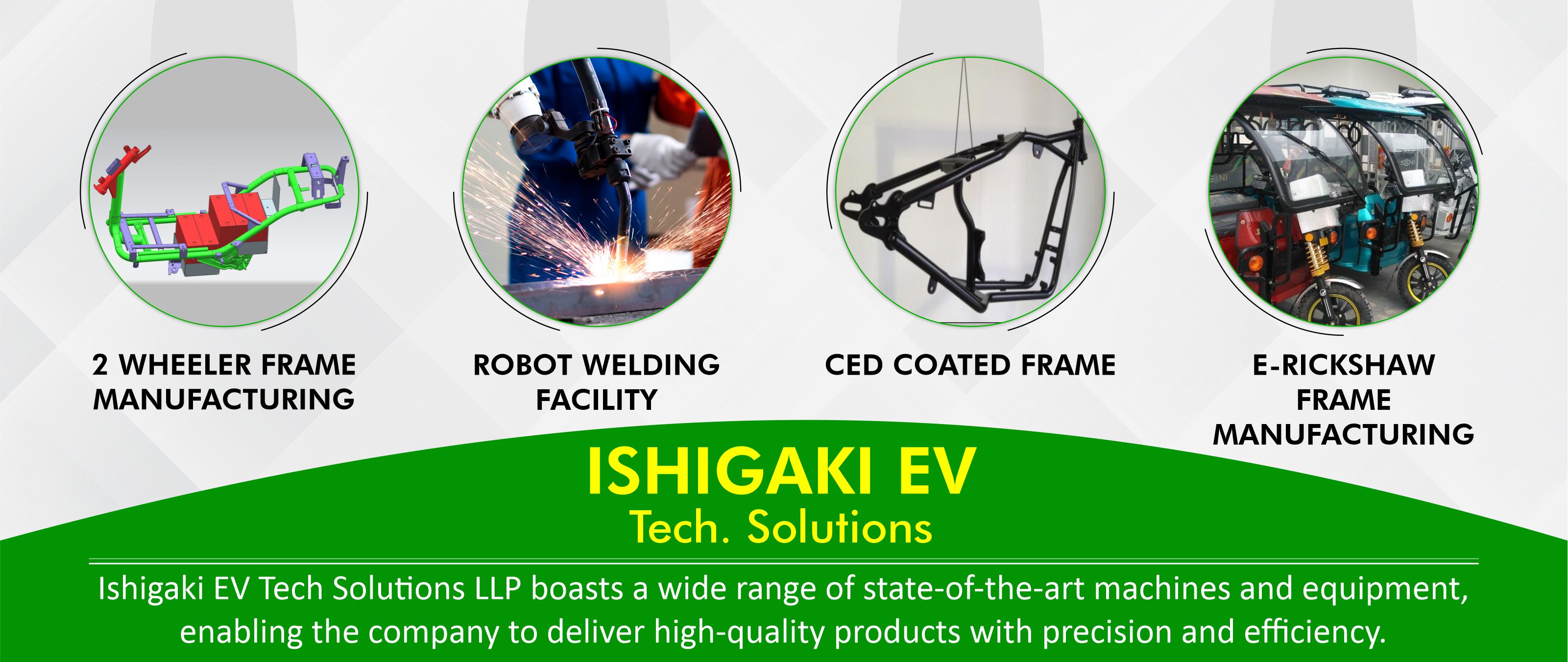

Great Experience in EV Industry

Welcome to ISHIGAKI EVTECH SOLUTIONS

Ishigaki EVTech Solutions LLP is a leading two-wheeler frame manufacturing company known for its highly skilled team, state-of-the-art facilities, and commitment to quality and precision. With its comprehensive range of sheet metal parts, welded assemblies, and full frame assemblies, the company serves electric vehicle manufacturers by providing cost-effective, high-quality components tailored to meet client-specific requirements. With a robust R&D setup and a client-centric approach, Ishigaki EVTech Solutions is a trusted partner in the industry, delivering products on time.

Our USP

We Offer Multiple Services

2 Wheeler Chassis Manufacturing

We specialize in crafting high-performance and energy-efficient two-wheeled vehicles Chassis, offering a seamless blend of style, safety, and innovation for a smooth and exhilarating ride.

Service DetailsRobot Welding Facility

Our cutting-edge facility utilizes state-of-the-art robotic technology to ensure precision and efficiency in welding processes, delivering superior quality and strength for diverse manufacturing applications.

Service DetailsCED Coated Frame

Our expert surface coating solutions enhance the appearance and durability of products, utilizing advanced techniques to provide a wide array of finishes, from glossy to textured, tailored to meet specific client needs.

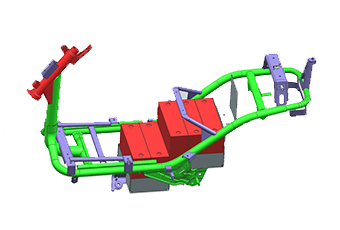

Service DetailsElectric Vehicle Frame Manufacturing

With a focus on advanced technologies and safety features, we are at the forefront of manufacturing L3 autonomous vehicles, pushing the boundaries of innovation for a safer and smarter future of transportation.

Service Details

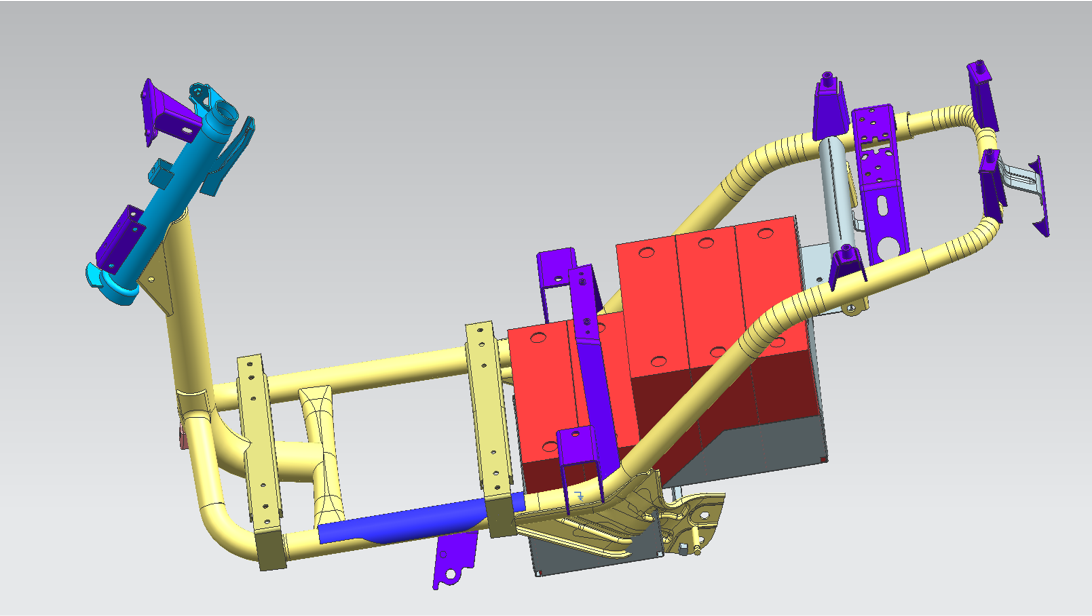

EV 2 Wheelers Chasis

We manufacture and assemble all kinds of two wheeler chassis mainly scooter and bike.

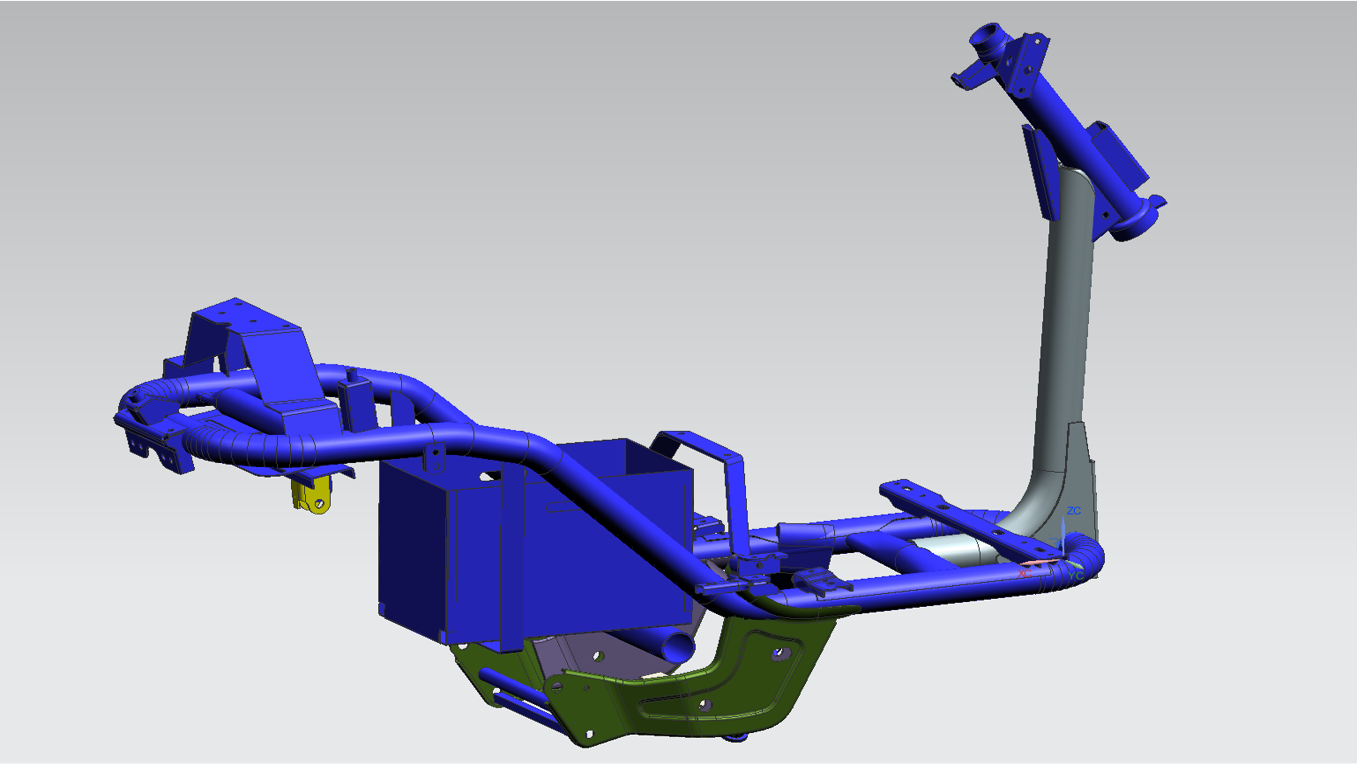

EV 3 Wheeler Chassis

We manufacture three wheeler chassis and assemble whole vehicle like Erickshaw or autorickshaw.

Assembly parts of two wheeler

We manufacture all sheet metal waste products like child parts of Chassis, battery box, almirah, bench, plates, etc

Working Process

How We Work

Client,s Feedback

Client,s Feedback

Need a Call Back?

We are always Ready To Help You

EV Scooter & Bike Chassis

Team ishagaki create and plan projects together with client after gathering their requirements. At our factory located in manesar gurgaon, where we use advanced computer programs to design things. Ishigaki's team of engineers come up with the advance design tools and other methodologies, and they make sure the designs can be manufactured using special tools. We also have plans to make sample versions of the products, which help the company come up with initial ideas for customers within the agreed time and quality standards.